Introduction

Making sure there is no water left in the input material is crucial prior to fat separation. This makes an effective cooker vital for any batch-based dry rendering process to operate profitably.

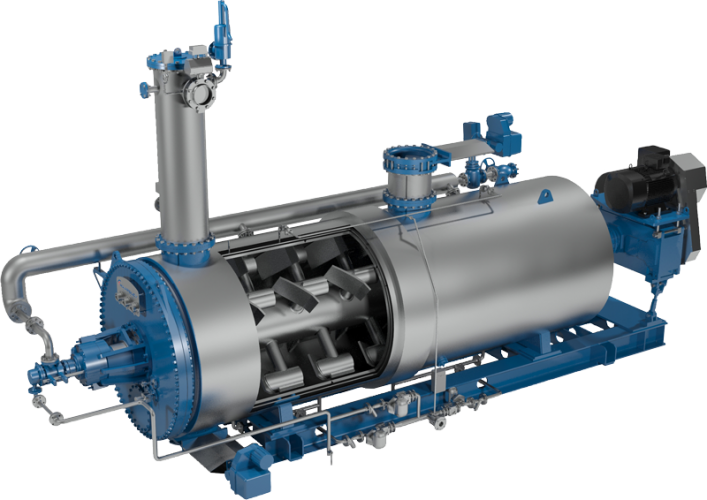

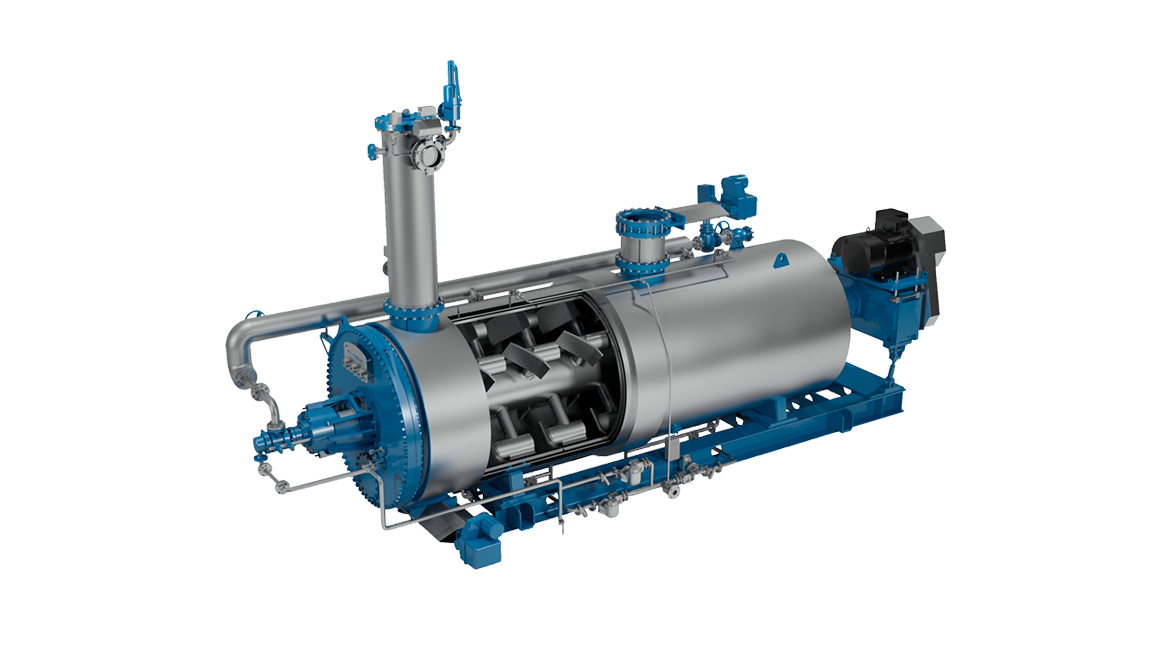

The Haarslev Batch Cooker is a straightforward, quick-to-install unit that you can bring on line quickly for the cooking, pressure cooking, hydrolysis or drying of an exceptional range of animal and poultry by-products. These include mixed meat offal and bones, poultry offal and wet feathers.

It can operate at the 133°C temperatures important for sterilization, and is ideal for smaller-batch processing of particularly large particles (up to 50mm) – which helps cut back on pre-cooking crushing requirements.

Furthermore, this solidly engineered, well-proven cooker can operate under pressures of up to 5 bar, ensuring your processing setup complies with the 2009/2011 EU Animal By-products Directive and can even process inputs containing hair, wool or feathers, for use in pet food. Cooking under pressure means any required sterilization can take place at temperatures down to 70–80°C.

Applicable for

- As part of high-temperature dry rendering lines in meat or poultry processing plants

- Poultry rendering operations involving hydrolysis of the feathers

- Straightforward, smaller-capacity batch cooking operations (less than 3 metric tons/hour)

- Pressure cooking animal by-products containing wool or hair into pet food