Introduction

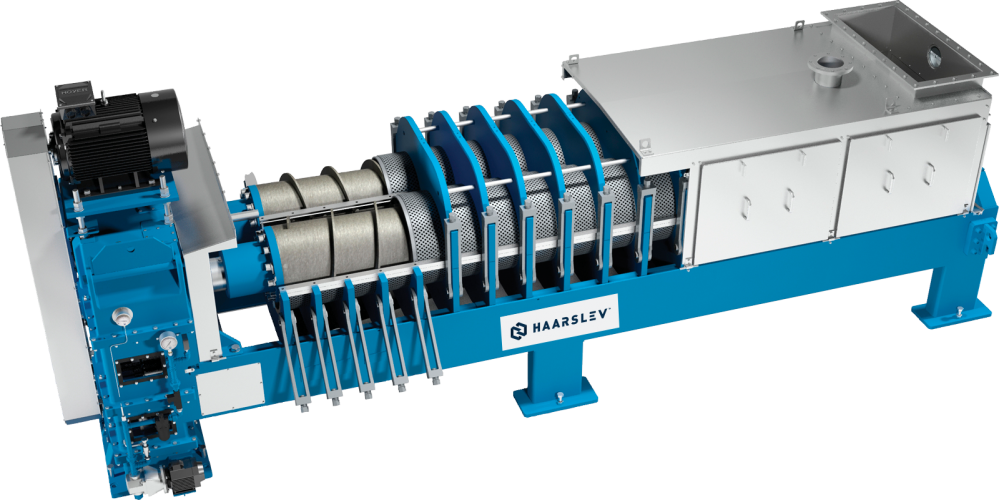

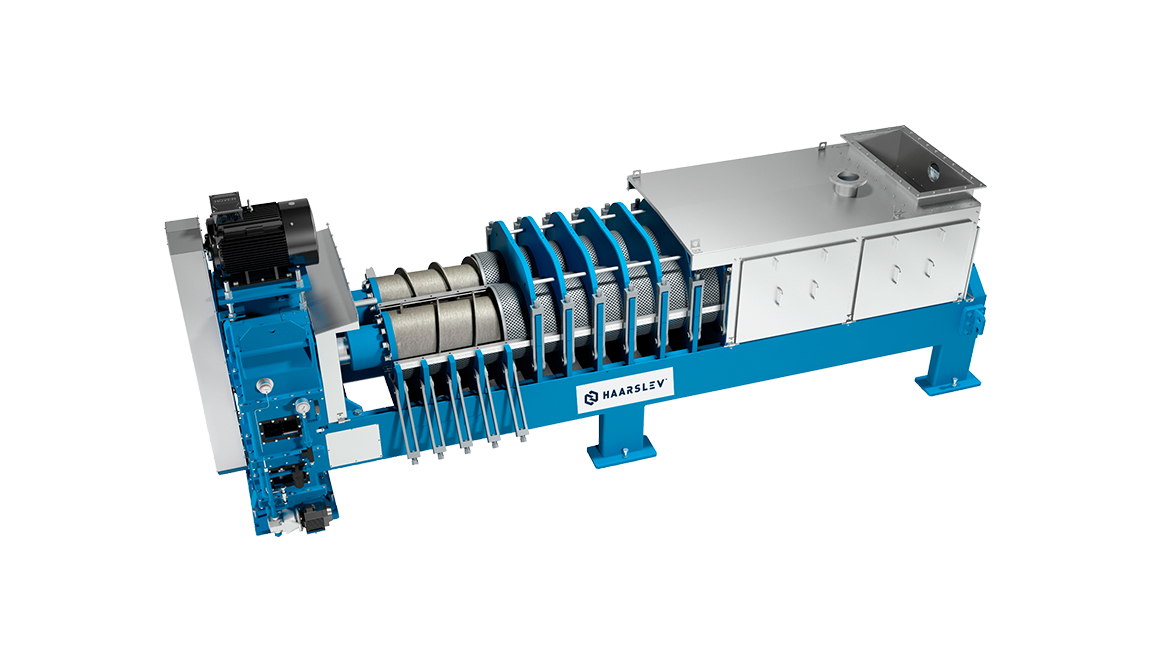

A Haarslev Twin-screw Press is ideal for extracting liquid from cooked fish or meat as part of wet rendering processes.

These units provide you with an effective way to remove water from the fats and solids content in cooked fish or meat. This then helps you improve the overall efficiency of subsequent processing and paves the way to significant energy savings.

These presses consist of two intermeshing, counter-rotating screws enclosed by a strainer shell and surrounded by a cover. There are bi-conical and cylindrical options, consisting of a conical shaft with either conical or cylindrical flights.

In both types, the flights of one screw reach almost into the core of the other screw, providing high compression and minimum slip and a more consistent press cake with a low content of both moisture and oil/fat.

Haarslev twin-screw presses are ideal as a reliable, slow-rotating (3 rpm) alternative to decanter centrifuges (3600 rpm). You can set the screws to turn at varying speeds to provide the flexibility you need to handle different raw materials and input volumes. For example, bi-conical configurations are better for use with soft fish. Bi-conical versions also provide higher liquid removal capabilities for any given rpm, compared to cylindrical presses.

Applicable for

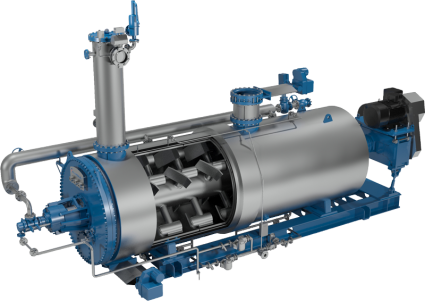

- Haarslev twin-screw presses are often used to extract liquid from cooked fish or meat as part of low-temperature wet rendering processes.

- They are also ideal as the first stage in mechanical dewatering processes, before the material enters a centrifugal decanter centrifuge.

- They can also be used in high-capacity feather plants.