Background

Lynetten, the largest sewage treatment plant in Denmark, treats industrial and municipal waste water of 1.1 million PE, corresponding to 3.2 million liters of waste water every day.

The waste water originates from the centre and parts of the suburbs of the city of Copenhagen. In 1980, Lynetten was founded with biological treatment and sludge incineration with two multiple-hearth furnaces.

Challenge

At the beginning of the 1990’s, a large project included biological removal of nitrogen and phosphorus in order to comply with new strict discharge limits. Further, the project involved digestion of sludge and the replacement of filter presses by centrifuges.

Solution & result

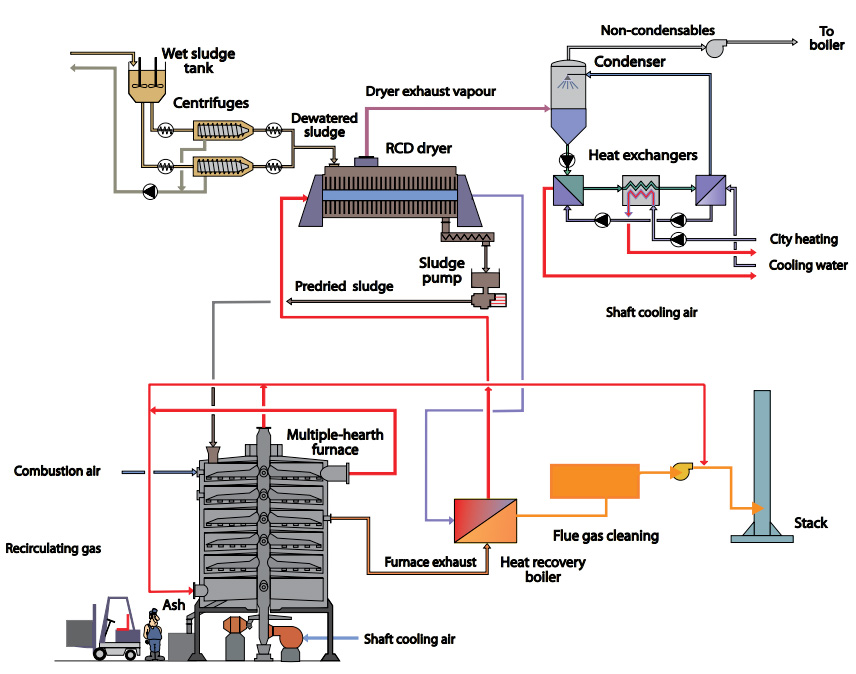

The incineration process was retrofitted with pre-drying by three Atlas-Stord RCD (Ring Channel Dryers) to improve energy economy and to boost capacity.

Previously, the dewatered sludge was led directly into the multiple-hearth incinerator, where drying took place. Removing pre-drying from the incinerators to the RCD dryers increased the incinerator capacity. Moreover, the quality of the flue gas improved as a result of the rise in the incinerator outlet temperature.

The dryers are indirectly heated with pressurized hot water from boilers, using the energy of the hot exhaust gases from the incinerators. The major part of the heat to the dryers is recovered from condensation of the vapor. This does not only fulfil the internal consumption of heat for buildings and technical processes at Lynetten; a considerable amount of heat is delivered to district heating for the city of Copenhagen.