Design Features

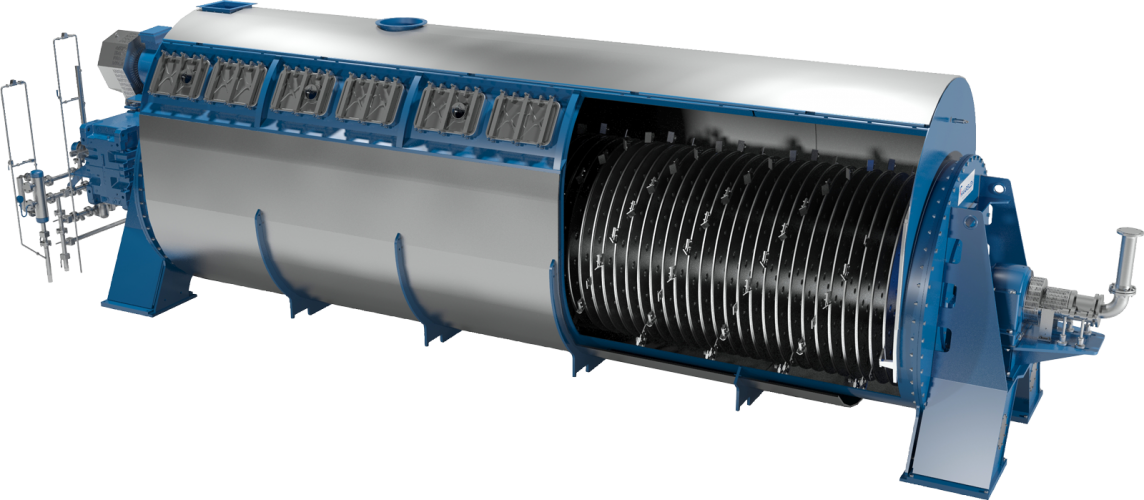

The rotor consists of a central pipe on which a large number of vertically arranged and conical discs with double walls have been welded. This design results in a concentrated heating surface offering maximum evaporation capacity in a compact design.

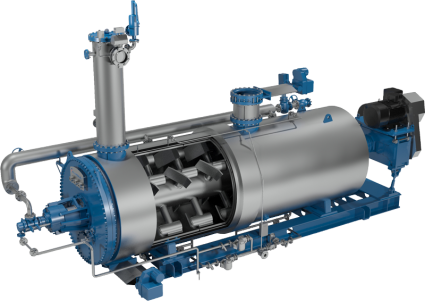

- The TST dryer is designed to operate with 6–10 barG steam pressure or alternatively with thermal oil.

- The dryer stator is manufactured in stainless steel. Rotors can be offered in mild steel or stainless steel design, depending on the characteristics of the product to be dried.

- The cone-shaped profile of the TST disc is especially designed for the processing of sticky and lumpy material.

Applications

The TST Dryers are designed for drying of sludge from municipal and industrial plants, as well as drying of residues from the pharmaceutical and chemical industries.

Quality

All TST dryers are carefully inspected by authorities. Furthermore, a pressure test is carried out before each shipment. The dryers are designed according to PED, ASME, GOST or marine standards (DNV, Lloyd’s, Bureau Veritas etc.).

Configuration

The dewatered sludge is fed to one end of the dryer. The moisture is evaporated when the material is conveyed through the dryer towards the discharge end.

The dryer can be configurated for various products. In order to further agitate and prevent the material from lumping, different scraper arm designs can be installed between the individual discs.