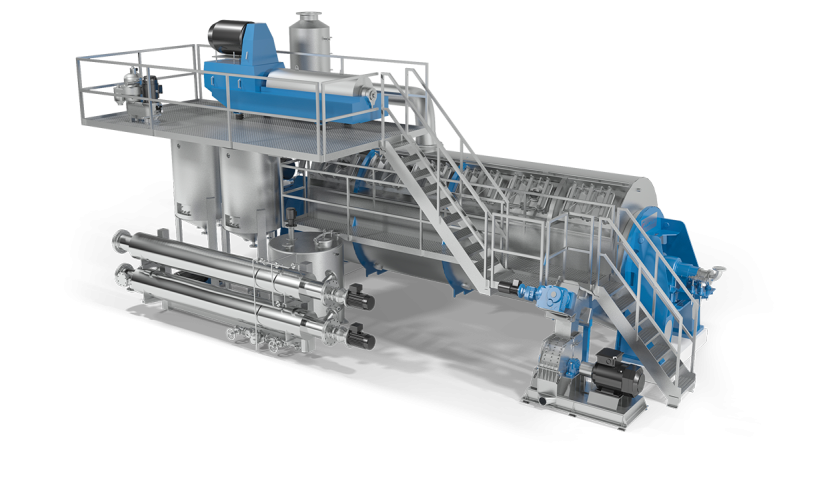

Compact, all-in-one units

Haarslev Onboard Fish Meal Plants are designed to meet worldwide demand for well-engineered, reliable processing equipment that can be slotted into the very limited spaces available below deck in trawlers and catcher processors.

A Haarslev Onboard Fish Meal Plant features a standardized cooker, press and dryer configuration, pre-assembled as a single integrated unit to take up the absolute minimum of space. There’s rarely enough room for repair work while at sea, so these specialist Haarslev fish meal plants are configured for exceptional reliability.

A Haarslev unit like this can be installed quickly and easily – you simply connect it to the onboard power supply and pipework, and are ready to go.

Standardized configuration

- Haarslev Twin-screw Press for quickly reducing water content prior to drying. Effective dewatering means using less steam in the drying process.

- Haarslev Disc Dryer, featuring a rotor with multiple steam-heated discs that apply indirect heat over a very large area. These dryers are famous for their reliability.

- Decanter centrifuge for improved oil recovery.

- Automated control system that provides control and monitoring from a tablet in different locations in the vessel.

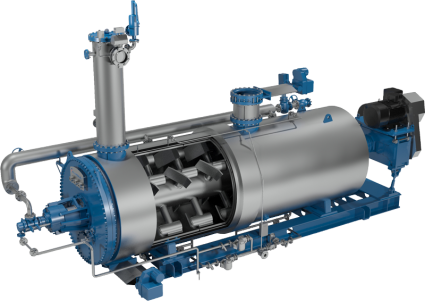

Compressed, customized units

Haarslev also provides larger shipboard fish meal processing systems, custom-engineered to individual vessel requirements, deck layouts and processing priorities, and with hardly any upper capacity limit.

These compressed systems provide savings of as much as 10–20% by recovering waste heat and using it to generate a lot of the steam needed on board. Using less fuel to produce steam and to run the onboard processing equipment means the ship can stay at sea longer, as well as reducing operating costs.

Standardized configuration

- Haarslev Waste Heat Compact Coagulator. Up to 70% less steam consumption for the cooking process, short retention time and higher-quality fish meal and oil.

- Haarslev Twin-Screw Press for quickly reducing water content prior to drying. Effective dewatering means using less steam in the drying process.

- Haarslev Disc Dryer, featuring a rotor with multiple steam-heated discs that apply indirect heat over a very large area. These dryers are famous for their reliability.

- Three-phase decanter centrifuge for separation of relatively homogenous inputs, or two-phase decanter centrifuge with a disc-stack centrifuge if the input raw material fluctuates in quality and composition.

- Fish oil polisher, for cleaning the fish oil so it remains fresh for longer and has higher commercial value.

- Advanced automation systems and tablet control options. Haarslev instrumentation and control systems make it easy to ensure meal outputs with consistent specifications.

- Evaporator system (optional – best for large installations).